|

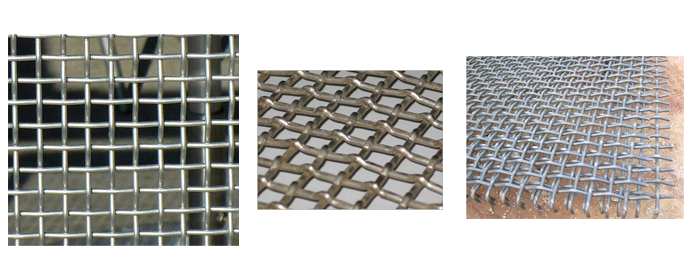

Vibrating screen equipment is sand production line, vibrating screen knit structure is pre-bent to form a corrugated metal wire, bend the two cards in the same location, the guarantee size, vibrating screen mesh of a two-way wave bending, tight lock bending, two-way separated wave bending, flat-top bending, bending a one-way corrugated, solid structure, used for mining, coal mining, construction, glass, oil, metal products industries.

First, change fine mesh method

1.The beam ring screw loose off, remove the frame, the fine mesh has been damaged is removed and replaced with a new fine mesh.

2.The fine mesh tile shaker mother online, put the frame back in place again, by hand around a fine mesh taut side of the fuselage on both ends of the upper frame and the lower frame edge of the box, each with a the universal clamp, the upper frame and the lower frame clamp.

3.The fine-mesh shaker four weeks protruding edge of the box in addition to reserve two centimeters, the rest all cut

4.Again put on the ring beam, loosen the universal clamp, screw the ring beam locking hook good.

5.Beat with a soft hammer beam uniformity ring around, and then copper nut, for the fine mesh is completed. If the shaker screen changing process, there is also the mother grid and movable plate is removed, you should note that when you replace the movable plate must be firmly embedded in the bottom surface of the inner flange network rack.

Second, change the parent network method

Shaker mother network, such as breakage, can repair itself, if you can not repair, please Depot repair, should prepare a set of female network backup.

Screen mounted on the frame

Install the screen frame is "field" shape, length 1860mm, width 560mm, two top to bottom line, caught in the middle screen, frame bolted to four weeks.

Screen for the original installation of a 14 and a 10 mesh screen PACKED, 14 mesh on 10 mesh screen mounted on the lower frame, using the effects are good, but there is a short life, screen Netease pressure collapse, tearing Jingwei stainless steel wire, resulting in breakage. Generally used 7-20 days began to appear damaged and scrapped.

To change this situation, in March 2008, through the Internet to find information, contact screen manufacturers, custom-designed for 10 meters width of 560mm aperture of 2cm thick diameter stainless steel mesh, wire diameter 2.5mm. The purpose of the macroporous custom thick wire diameter stainless steel mesh is to make it instead of the bottom 10 mesh stainless steel screen to increase the framework of "Dan King" to avoid salt collapsed upper 14 mesh filter screen, imagine science practical application effect Not bad. A month later, due to the angle iron frame loose crimp the outer frame with the sieve of 14 mesh screen by pressing edges broken off, when removed replaced, and 14 found that as 2.5cm net mesh and in direct contact with the frame, rigid connection, a lot of the edge off the vibrating steel strong 2.5cm mesh. Then simply between the frame and the screen up and down all padded scrap book conveyor, vibration improves the thick filament breaking phenomenon. When replacing Again, no vibration occurs off the situation.

last:Hot galvanized steel wire mesh performance index

next:Facades Paul Wimbledon Plaid knowledge

|